the contradiction at the core of vegetable oils

Vegetable oils are among the most widely consumed food ingredients in the world. They are present in everyday cooking and in nearly every processed food. Yet the way they are produced follows a logic that no longer aligns with today’s challenges.

The global industry is optimized for maximum yield through centralized, energy-intensive, chemistry-based processes. Nutritional quality, environmental cost, and downstream impacts are treated as secondary variables.

At the same time, protein-rich plant material — a critical resource in a world facing climate pressure and protein scarcity — is largely diverted into industrial animal feed, reinforcing one of the most resource-intensive food systems.

This is not a technological limitation. It is a systemic contradiction.

Oleovita starts from this point.

global vegetable oil production today

In the pursuit of a healthier diet, many choose vegetable oils for cooking. They are also a major ingredient in processed foods, from baked goods and snacks to ready meals and sauces. Globally, over 200 million tons of vegetable oils are produced and consumed each year, with sunflower, rapeseed, and soy oil making up the majority. Their widespread use is driven by affordability and versatility, making vegetable oils a nearly invisible yet essential part of modern diets around the world.

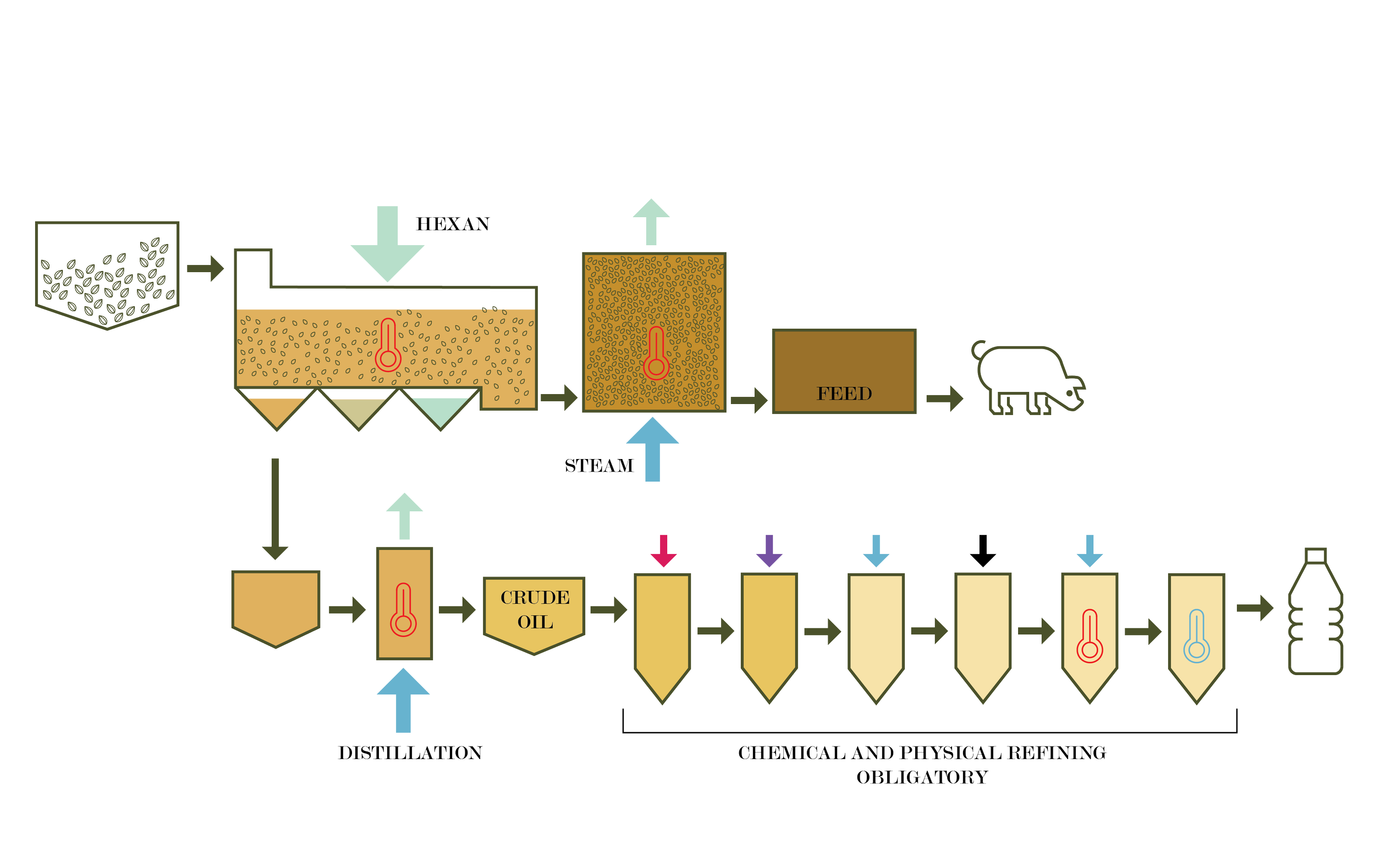

98% of vegetable oils on the market today are produced using chemical solvent extraction. This is a process designed to maximize yield rather than preserve quality. After seeds are crushed and heated, oil is extracted using hexane, a petroleum-derived solvent.

After solvent extraction, the crude oil is not fit for human consumption. In its untreated state, it contains toxic residues, free fatty acids, and other undesirable compounds that make it potentially harmful if ingested. To render it edible, the oil must therefore undergo extensive chemical refining, including degumming, neutralization, bleaching, and deodorization.

While these refining steps improve shelf stability and visual appearance, they also remove many naturally occurring bioactive compounds, such as polyphenols, tocopherols, and other antioxidants. The end product is a highly standardized, ultra-processed oil designed primarily for industrial performance rather than nutritional value.

Although efficient, hexane is a neurotoxic substance. In the human body it is metabolized into 2,5-hexanedione, a compound known to damage the nervous system and affect reproductive health. Residual solvent does not need to be declared on food labels if it remains below legally permitted limits. But the regulatory limits governing solvent residues and processing aids are largely based on decades-old legislation. They are increasingly viewed as insufficient given current scientific understanding and consumer expectations.

For vegetable oils, the European Union sets a maximum limit of 1 mg/kg for residual hexane. In contrast, animal feed is allowed to contain up to 1,000 mg/kg. After chemical solvent extraction, the remaining by-products from oilseeds—often containing residual hexane—cannot be used for human consumption and are therefore commonly fed to animals. These animals, however, eventually enter the human food chain, meaning that the solvent may also reach the human body indirectly.

From an environmental perspective, solvent extraction is highly polluting. Each year, large quantities of hexane are released into the atmosphere, alongside chemical waste from refining steps such as degumming, neutralization, bleaching, and deodorization.