innovative cold-pressing technology

OleoVita’s approach is based on mechanical precision rather than chemical intervention.

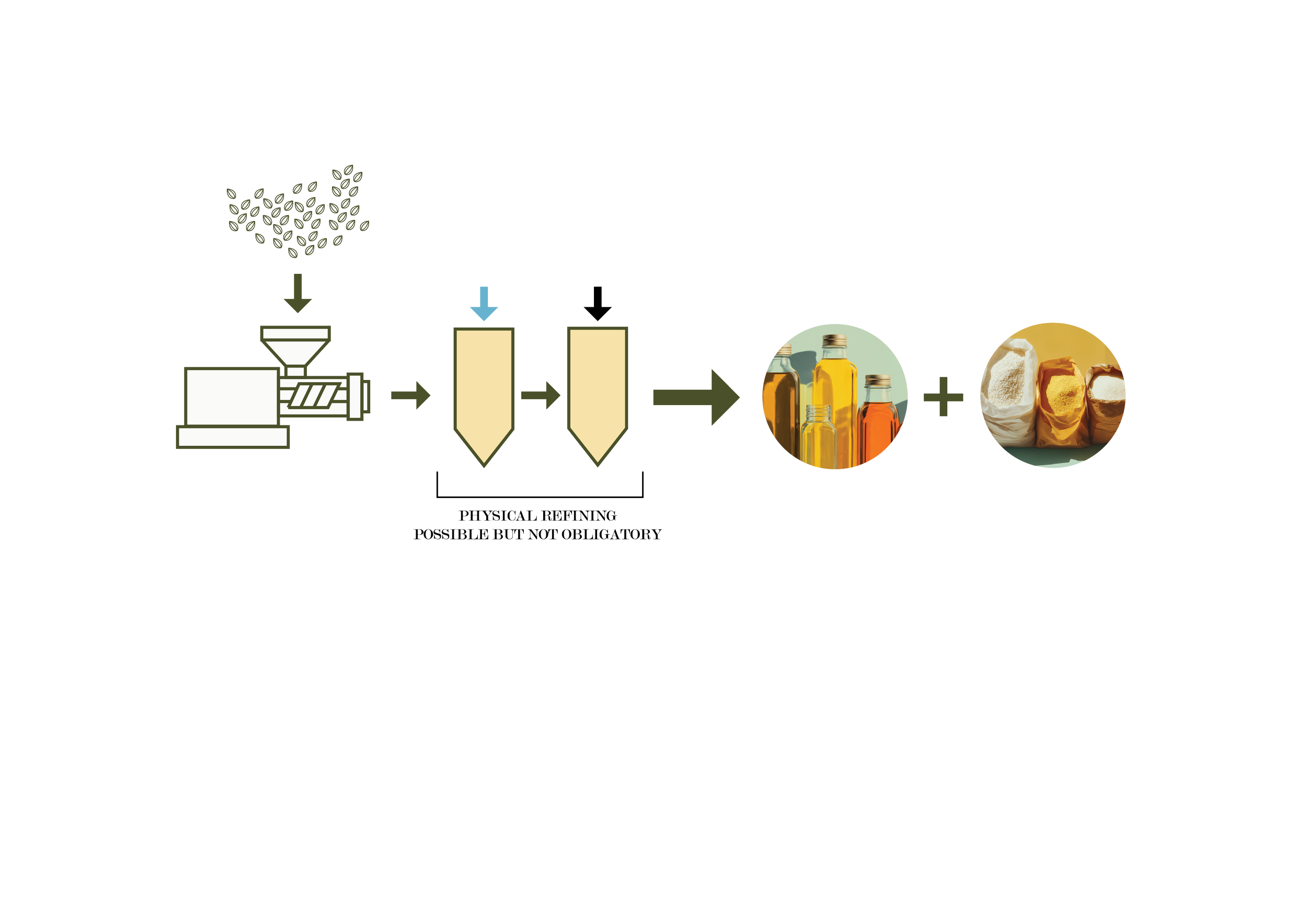

Our oils are produced exclusively through cold mechanical pressing, without the use of solvents, hexane, or chemical refining agents. While mechanical pressing itself is not new, OleoVita applies a patented technology that fundamentally improves efficiency, separation, and yield — clearly distinguishing us from conventional producers. The entire process is designed to preserve the natural integrity of the raw material, from harvest to final product.

Our proprietary process enables a significant reduction in processing temperatures compared to standard extraction methods, preserving the intrinsic qualities of the raw plant material. Lower temperatures are critical, as excessive heat degrades sensitive compounds such as phenols, carotenoids, flavonoids, tocopherols, and other bioactive components that contribute to taste, nutritional value, stability, and shelf life. Through controlled low-temperature extraction, accelerated filtration, and inertized transfer and storage environments, Olevita safeguards oil quality from harvest to final product.

Our process is defined by:

0% chemistry, 0% hexane

mechanical extraction at controlled low temperatures

no refining, bleaching, or deodorization

direct processing of the harvest to minimize oxidation and degradation

By avoiding chemical solvents and high heat, OleoVita preserves the oil’s natural fatty acid profile, along with micronutrients and bioactive compounds that are typically lost in conventional extraction. The result is an oil with higher nutritional density, superior sensory quality, and enhanced safety — a truly pure oil. At the same time, the process delivers measurable energy savings and eliminates solvent emissions, chemical waste streams, and energy-intensive refining steps, significantly reducing environmental impact.

One of the main reasons cold-press technology is often avoided is its traditionally low oil yield, which limits efficiency and leaves behind residual material with limited value. OleoVita’s high-efficiency cold-press technology overcomes this limitation, delivering substantially higher yields while maintaining low temperatures. The residual material contains minimal oil and is transformed into a dry, protein-rich flour.

Because the technology performs equally well with both seeds and nuts, it enables the production of oil-free seed and nut flours rich in protein and valuable nutrients. With full technical control of every phase of the extraction process, complete traceability, and the ability to work flexibly. The potential applications are wide-ranging, limited only by imagination.

Oleovita is a decentralized bioeconomy platform for food-grade oils and proteins, built on advanced mechanical extraction and data-driven process control.