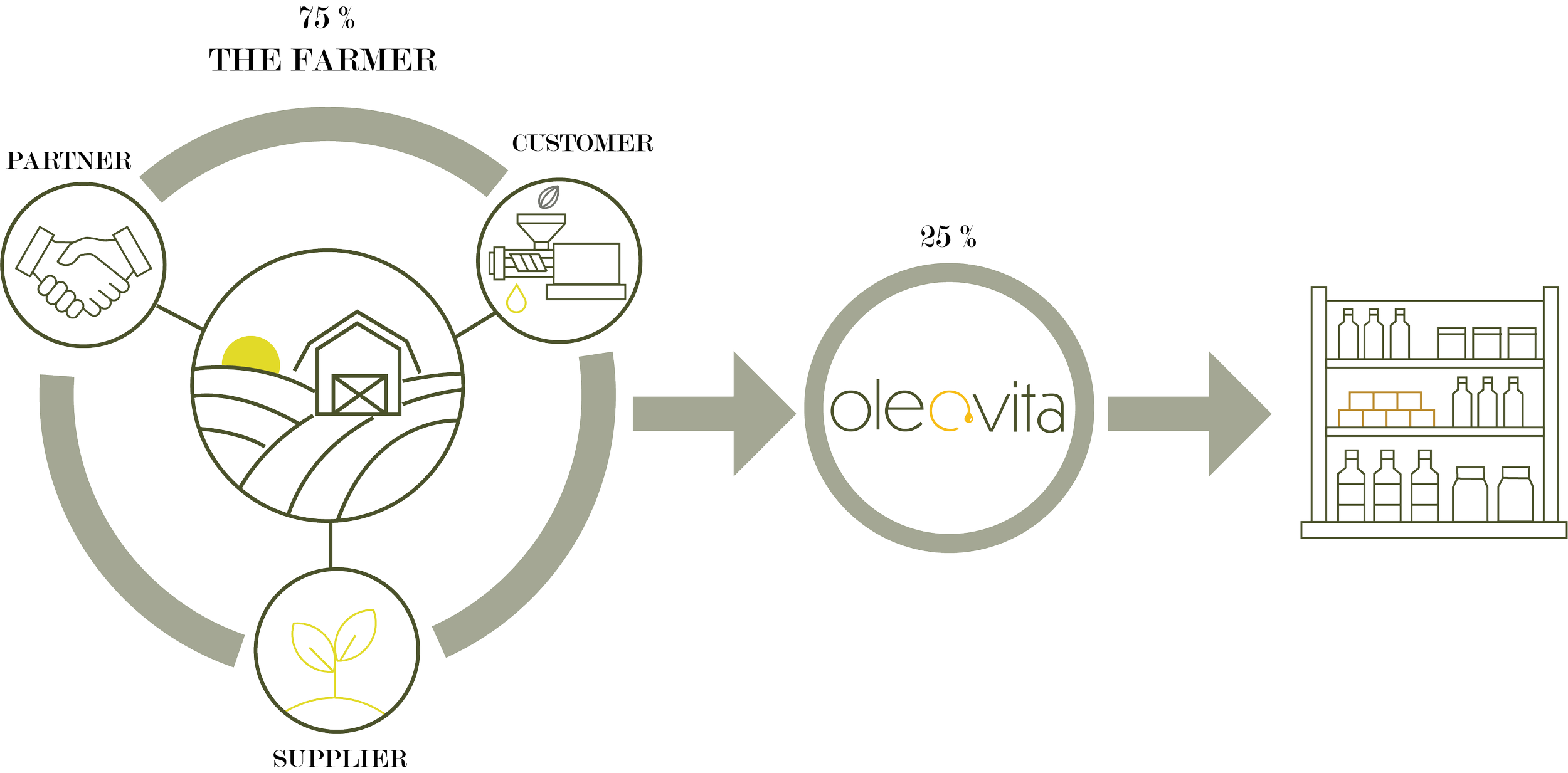

redistributing value through decentralization

Instead of concentrating production and value in a few industrial facilities, OleoVita decentralizes processing and reconnects it to the agricultural source. Farmers become active participants in the production system, not just raw material suppliers.

Value is generated closer to where resources originate and shared across the network.

OleoVita provides the technological infrastructure, quality standards, and system coordination needed to operate at industrial scale — without reverting to centralized control. The result is a model that is:

economically resilient

scalable across regions

aligned with environmental and social responsibility

OleoVita is the result of five years of industrial field operations. Our patented hardware is a mature technology, not a prototype, further validated by the University of Turin with a benchmark of 6.16% residual oil in plant proteins—setting a new efficiency standard for mechanical cold-pressing.

We are now bridging mechanical mastery with the digital future through a dedicated AI Research Development program. By integrating acoustic and thermal sensors, we are developing a Predictive Maintenance and Dynamic Yield system. Our goal is a self-learning ecosystem that eliminates downtime and optimizes every batch, ensuring global scalability.

The future will be built through collaboration and shared success.